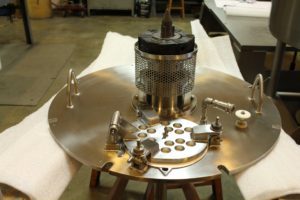

Reduce the batch mixing cycle by 50% or more with the Containerized Batch Mixer (CBM) from Readco Kurimoto. Our versatile and efficient systems of modular batch mixers offer optimal blending and processing for dry powders and granular materials. The high-speed impeller, combined with a unique tumbling action, breaks up clumps and allows for a more thorough and even blend and finer dispersions than just tumbling alone.

The CBM system of powder mixers gives manufacturers complete flexibility and control over their dry powder blending and processing.

Experience Unmatched Efficiency With Our Dry Powder Batch Mixers

Discover a modular design that meets your every processing requirement, from small batches to large-scale operations. Unlike traditional batch mixing systems, the CBM vessels can be dedicated to a particular formulation or color. Allowing reduced or eliminate cleaning between batches.

Load ingredients, blend them, and discharge them in a seamless, ongoing process. This fluid cycle blending system never has to be shut down for cleaning. The unique modular design means one module can be charged, one can mix ingredients, another can be emptied, and another can be cleaned.

Small amounts of liquid can be dispersed into the powders if required.

Downloads:

Containerized Batch Mixer Brochure (PDF)

RK Labmaster (PDF)

Learn More About Readco Kurimoto High-Speed Batch Mixers

Ready to upgrade your powder mixing operations? The Containerized Batch Mixer from Readco Kurimoto offers numerous advantages regarding product quality, process efficiency, and cost savings. Contact us today or request a quote and learn how our batch mixer systems can benefit your business.

Engineered and built in the United States of America

Engineered and built in the United States of America