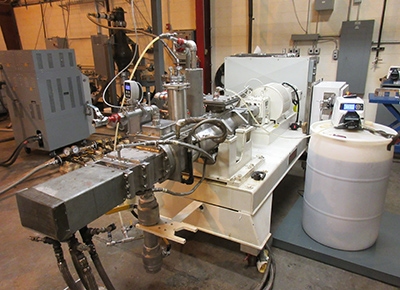

For manufacturers that work with unique materials, it can be difficult to identify an ideal industrial mixing solution. At Readco Kurimoto, LLC, we offer a range of industrial mixing solutions to help our customers handle high-viscosity pastes and slurries, as well as other difficult materials. We provide continuous chemical reactions and continuous devolatilization of high-viscosity materials through careful control systems, enabling us to support track-and-trace production, formula and recipe management, and quality control.

Key Standards and Other Capabilities

With continuous processing of specialty materials, you eliminate problems with inconsistency between batches to drive more efficient and on-demand production. Manufacturers who incorporate our Self-Contained Processor, Continuous Hybrid Reactor, and/or Continuous Processors into their production lines gain benefits such as:

- More efficient on-demand production

- Smaller machinery footprint

- Short residence time and heat history for mixing

- Long residence time and high heat transfer area for reaction

- High dispersion levels for mixing

- Built with durable specialty materials to handle corrosive/abrasive chemicals

- Fully automated production

- Low maintenance requirements

- Support for Just-in-Time production practices

- Ability to operate without material for cleaning and process startup

The Readco Kurimoto team designs our equipment for compliance with numerous industry standards, including ASTM, NIST, ASME, and more. We will never sell you a machine without first testing it in our lab to ensure it will work for your product and integrate seamlessly into your existing processes.

The Readco Kurimoto team designs our equipment for compliance with numerous industry standards, including ASTM, NIST, ASME, and more. We will never sell you a machine without first testing it in our lab to ensure it will work for your product and integrate seamlessly into your existing processes.

Additionally, we never discuss our customers with anyone. We adhere strictly to all confidentiality agreements. Many of our customers consider us a trade secret.

What are Continuous Reactors?

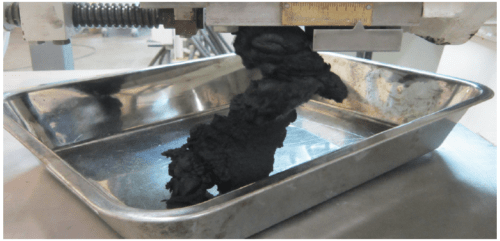

Continuous reactors get their name from the continuous flow of reactants into the machine, resulting in a continuous flow of reliably mixed products from the system. Industries that process large quantities of chemicals often prefer continuous reactors for their faster processing speed and reliable mixing capabilities.

Compared to batch processing, continuous processing offers lower risk and cost than batch processes over time. We also have different machine sizes available for different needs, including use in harsh processing environments. For more information, here are 10 reasons that continuous processing is better than batch mixing.

Learn more about the products we’ve worked on by downloading our case studies.

- Activated Carbon

- Activated Carbon (High Temp)

- Asphalt

- Ink

- Metal Injection Molding

- Pre-Preg Carbon Fiber Resin

- Styrene-Butadiene Rubber

- Precise Moisture

- Systems Control

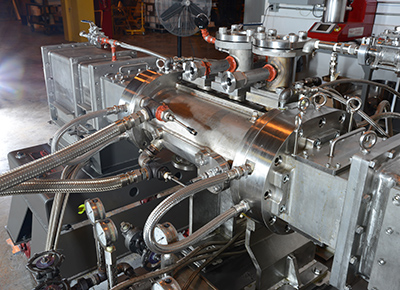

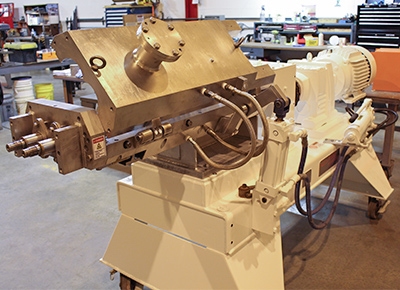

Continuous Processor from Readco Kurimoto, LLC

The Continuous Processor from Readco Kurimoto, LLC features a proprietary power transmission design and bearing configuration that allows them to operate safely while running empty. Readco units automatically prevent the mixing elements from contacting the barrel and eliminate any risk of contamination from metal-to-metal contact, allowing safe startup or cleaning without any material in the process. For more information, please check out our FAQ.