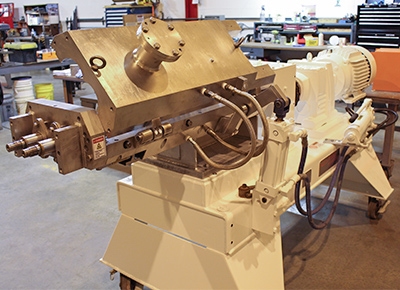

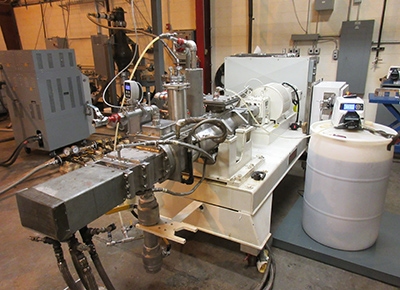

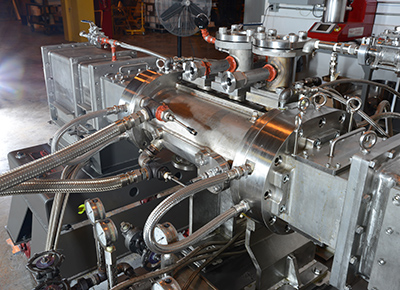

The chemical sector requires advanced equipment to facilitate carefully balanced chemical reactions. While many continuous processing solutions on the market can’t handle deep-vacuum processing of high-viscosity and/or “sticky” chemicals, the Continuous Hybrid Reactor (CHR) and Self-Contained Processor (SCP) from Readco Kurimoto have been designed to accommodate continuous devolatilization of high-viscosity and/or “sticky” materials under various adjustable levels of vacuum. For applications that do not require vacuum the Continuous Processor (CP) is often used as one of our most versatile machines for this industry. In conjunction with control solutions from our partner Melfi Technologies, Inc., our equipment provides:

- Formula and recipe management

- Superior quality control

- Track and trace production