Pet owners increasingly demand high-quality food and care products for their pets, which has begun to blur the lines between food and supplements for humans and pets. This trend has put significant pressure on original equipment manufacturers (OEM) in the pet products sector to improve their processes and enhance the quality of the goods they produce.

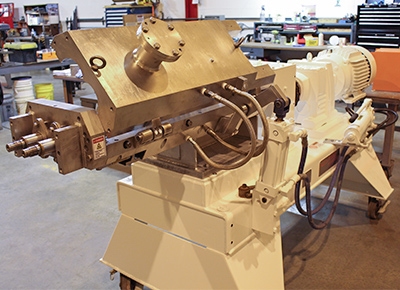

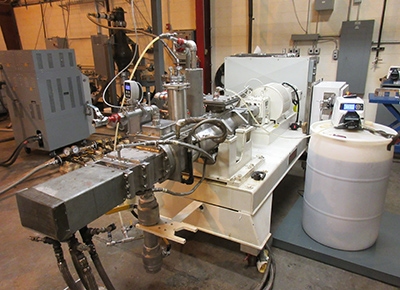

At Readco Kurimoto, we specialize in designing and manufacturing advanced industrial mixing equipment. We can provide pet food and product OEMs with the means to consistently and efficiently mix high-viscosity doughs, pastes, and slurries. Along with our industrial controls partner, Melfi Technologies, Inc., we can enable superior quality control, track and trace production, and enhanced formula and recipe management for pet product manufacturing operations.

Advanced Mixing Technology and Process Automation for Pet Food Production

Readco Kurimoto offers innovative cat and dog food processing equipment that we custom-design and manufacture to meet each customer’s unique needs and specifications. We focus on automated technologies that provide numerous advantages:

- Improved product consistency: Implementing automation eliminates human error, ensures strict adherence to recipes, and maintains optimal manufacturing conditions. The result is consistent, uniform products that meet customer expectations.

- Enhanced quality control: Our mixing equipment for the pet food industry provides maximum precision and real-time monitoring capabilities, adding substantial value to your quality control processes.

- Increased operational efficiency: Automated mixing equipment can boost productivity by reducing manufacturing time and facilitating quick and dynamic formula changes, enhancing your operational capabilities.

- Energy savings: We’ve designed our technologically advanced automated mixing machines to consume less energy, which can reduce operating expenses and boost your company’s bottom line.

Engineered and built in the United States of America

Engineered and built in the United States of America