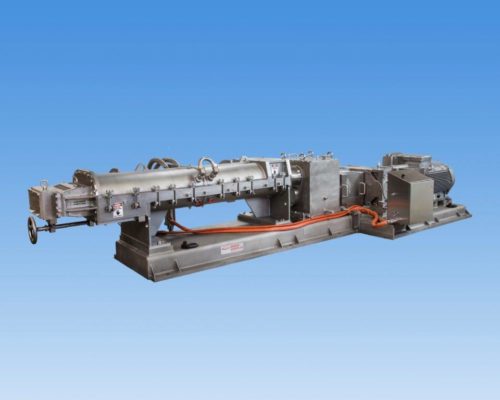

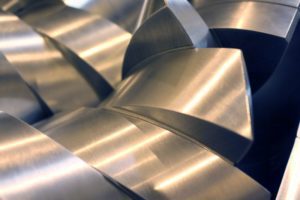

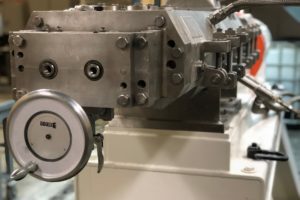

Readco’s Continuous Processor (CP) has been serving a large range of industries for over 60 years. This equipment can mix multiple dry materials with multiple liquids continuously, ensuring a homogenous mix at the end of the mixing cycle. Its durable design allows it to handle high-shear and high-viscosity materials with ease. It doesn’t stop there — the Continuous Processor can also be used for low-viscosity applications and gentle kneading.

Trust Readco Kurimoto LLC to deliver quality continuous mixing equipment that meets the most stringent processing needs.

What Is a Continuous Mixer?

Continuous mixing is a process that creates a consistent mixture of solid and liquid materials by precisely metering the raw materials as they enter a mixing chamber and then subjecting them to the required amount of shear intensity. Individual raw materials are constantly fed into the processor, mixed, and then homogenous material is discharged. This process is often used in industrial settings to streamline and automate production on a single, uninterrupted line.

Continuous mixing eliminates irregularities often associated with batch-to-batch variability. The raw materials are added at a consistent ratio to ensure optimal product quality while maintaining the maximum degree of throughput. Additionally, indirect heating or cooling is available as required to obtain the product characteristics and/or specifications.

The entirely enclosed design of the mixing chamber is helpful in two ways, depending on the application. For starters, it prevents external pollutants from contaminating the product being blended. Second, it aids in the reduction of unwanted emissions in production.

Downloads:

Continuous Processor Brochure (PDF)

RK1 Lab Size Continuous Processor (PDF)

Connect With Readco Kurimoto LLC for More Information on Our Continuous Processor

Consider utilizing a continuous mixer if you need a dependable method of mixing one or more powders with one or more liquids, with enhanced quality and increased throughput. Using this versatile piece of machinery will assist you in producing a more uniform end product while decreasing material waste and enhancing product quality.

If you need a supplier of high-quality continuous mixers, count on Readco Kurimoto LLC. Our Continuous Processor is the perfect choice for you. Contact us today to learn more about the continuous processor and how it can benefit your business.

Continuous Processor Videos

Click any video to play

Engineered and built in the United States of America

Engineered and built in the United States of America