Producing high-performance sealants and adhesives requires consistency and precision. Readco Kurimoto specializes in continuous batch processing for sealants and adhesives, offering industrial mixers engineered to handle your most challenging formulations. Our systems are designed to manage highly viscous materials and chemically reactive compounds without compromising safety or throughput.

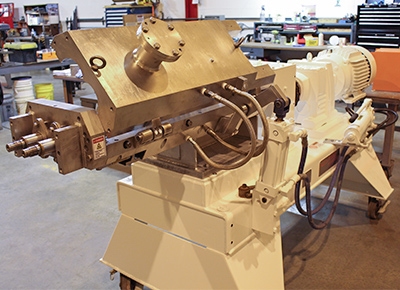

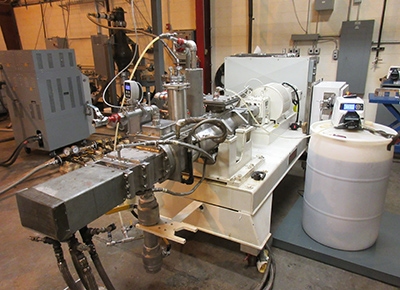

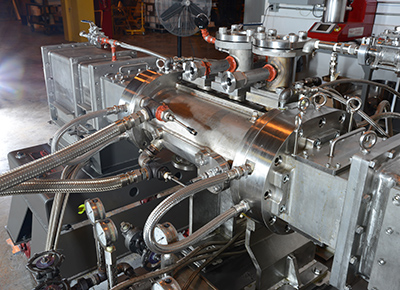

State-of-the-Art Mixer and Mixing Systems

Traditional batch mixers often introduce inefficiencies into production. That’s not the case with Readco Kurimoto’s continuous mixers for adhesive and sealant mixing. Our mixers eliminate batch-to-batch inconsistencies and reduce cycle times. Our custom-engineered systems allow for seamless adhesive batch mixing and sealant batch mixing, with enhanced control over shear, temperature, and residence time.

Our proprietary continuous mixing systems deliver highly uniform outputs for each product run, regardless of the viscosity or reactivity of the input materials. From PVA glues and caulks to polyurethanes and epoxies, Readco Kurimoto equipment is optimized for continuous batch mixing for adhesives and sealants. The result is a final product that meets or exceeds quality specifications.

Process Control and Automation Integration

Every Readco Kurimoto system includes advanced automation capabilities. Integrated sensors and control systems allow for real-time monitoring and process validation, helping clients maintain traceability and compliance with standards like ASME, OSHA, and USDA 3A Dairy. These features reduce the risk of costly errors.

Our continuous processors are engineered to reduce material waste, eliminate manual handling errors, and limit downtime. By replacing traditional batch methods, our clients achieve higher ROI through greater output, lower maintenance demands, and minimal storage requirements.

Continuous pharmaceutical processing involves a seamless, automated material flow through a closed system, ensuring purity, uniformity, and efficiency. Industrial continuous batch processing follows similar principles but is tailored for large-scale operations like sealant and adhesive production, where customization and material resilience are critical.

Applications of Our Mixing Solutions

Our industrial mixers and continuous manufacturing equipment can be used for many applications, such as:

- Adhesives

- Caulking

- Epoxies

- Medical adhesives

- Polyurethanes

- PVA glues

- Sealants

Trust Readco Kurimoto for Reliable Continuous Mixers

Our machines are built using standard 316 stainless steel wetted parts, with options for Hastelloy®, Alloy 20, and tungsten carbide for harsh environments. All equipment meets or exceeds ASTM and ASME standards for long-lasting, compliant performance.

Readco Kurimoto’s continuous mixing solutions are built to address the complexities of adhesive and sealant manufacturing. Whether handling moisture-sensitive materials or high-viscosity pastes, our machines are engineered for:

- Consistency. Our precise equipment is built to guarantee consistent products with no batch-to-batch variation.

- Production. Our equipment can accommodate on-demand and just-in-time production.

- Safety. The equipment features an enclosed design for enhanced sanitation.

- Cost-Effectiveness. Our units are low-maintenance, with extended lifespans that don’t compromise on quality. The units are also fully automated to save you costs on labor and manual processes. Our equipment reduces the need for excess storage, further cutting costs.

- Lab Testing. We offer a virtually 100% success rate for products, backed by lab testing processes to vet the capacity and viability of products.

- Simplicity. Our batch processing units are designed to integrate with virtually any preexisting processes.

At Readco Kurimoto, we offer risk-free consultations as well as demos of our process development with customer-provided materials.

Contact Our Team

If you are looking to gain a competitive advantage, Readco Kurimoto, LLC is a perfect choice for your most challenging processing needs. Fill out the form to contact our team and discuss your needs. We’ll be in touch shortly.

Learn more about the products we’ve worked on by downloading our case studies.

Partner With Readco Kurimoto Today

Headquartered in York, PA, Readco Kurimoto, LLC has over a century of expertise in designing and manufacturing world-class continuous processors. With a steadfast commitment to innovation, we deliver machinery that helps clients streamline production.

Looking to improve performance and reduce risk in your adhesive or sealant operation? Contact Readco Kurimoto to request a quote and to discover the benefits of our continuous mixers for adhesive and sealant mixing.

Engineered and built in the United States of America

Engineered and built in the United States of America