Advanced Continuous Mixing Solutions for the Building Products Industry

Readco Kurimoto’s continuous mixing machines are ideal for producing various building products on a large scale. Our high-performance solutions can help you meet production deadlines and generate the same level of quality each time. Our innovative solutions also adhere to OSHA and ASME pressure vessel standards, enabling your business to remain compliant.

While continuous manufacturing may have higher upfront costs, the increased efficiency of this equipment will lead to your ROI being realized quickly. Investing in our solutions enables you to produce different building products, like:

- Shingles

- Roof coatings

- Carpet backing

- Loaded polyurethane foam

- Joint compound

- Gypsum board

- Caulk

- Plummer’s Putty

- Construction Adhesives

- Synthetic stone and brick

- Reflective marking materials

Producing these products with our solutions is efficient and convenient because they provide:

Material Homogeneity and Uniformity

Building products often consist of various materials, which manufacturers must mix properly to ensure consistent quality across all items. For instance, batch mixing components in asphalt roofing manufacturing can cause inconsistencies in shingle thickness, saturation, and granule adhesion. However, producing asphalt shingles using a continuous processor ensures constant, uniform mixing of constituents. Your team can also easily monitor and control the process in real time.

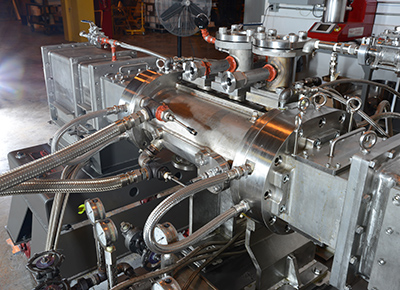

Moisture and Solvent Removal

Certain building products, like epoxy and acrylic, must have a low moisture content to ensure their reliability. With our SCP equipment, you can reduce product moisture through distillation or evaporation.

Color and Texture Consistency

Building products like synthetic stone and brick must retain a natural-looking appearance to provide an aesthetic appeal. Our machines provide precise color and texture control by distributing aggregates, additives, and pigments uniformly throughout the mixture, enabling you to attain the desired appearance.

Viscosity Uniformity

Batch mixing for commercial coatings causes variations in viscosity, impacting product quality. With our continuous manufacturing equipment, you can handle materials of any viscosity and achieve uniform mixtures.

Asphalt Roofing Material Case

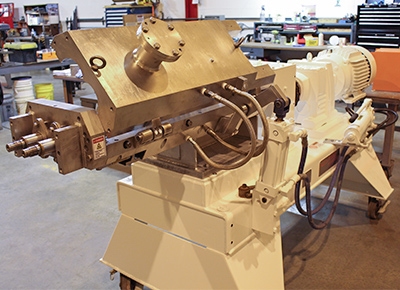

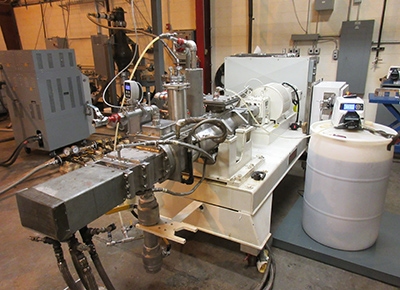

One of our customers in the building products industry required a system to meet their individual application requirements. Specifically, this customer needed equipment that would allow for the dispersal and dissolution of fillers and additives into asphalt with fast residence process speeds. They also required dual processors to help reduce or eliminate the need for heating large mix and storage tanks for long periods of time.

Although asphalt benefits from the introduction of certain additives such as oil and rubber pellets, the traditional process for incorporating them is often time-consuming. In addition, the process needs to hold the temperature of the material at over 300° F, which consumes a lot of energy.

Benefits of Investing in Readco Kurimoto’s Continuous Manufacturing Equipment

Streamline home service industry manufacturing with Readco Kurimoto’s mixing solutions. Our systems allow for consistent production, eliminating the risk of variations from batch to batch. They also offer fully automated production, more efficient on-demand production, just-in-time production, and an enclosed design.

Our continuous manufacturing equipment helps reduce maintenance and provides consistent reliability to meet your steady production needs. We build our equipment to provide long-lasting service and 24/7/365 operation without sacrificing quality for cost. We also perform lab testing to determine a machine’s scale-up capacity and ensure your products can be made with a 100% success rate.

To facilitate installation, our equipment integrates with existing processes while eliminating excess storage. In turn, you can experience the advantages of our equipment without compromising the integrity of your current upstream and downstream systems.

Other reasons to choose us include:

- Commitment to your success: We are dedicated to designing and building systems that maximize your potential for success. With integrity as our guiding principle, you can feel confident knowing we have your best interests in mind.

- Expert solutions from a talented team: Readco Kurimoto has invested in an experienced, qualified, diverse team to help us meet your expectations. We prioritize your needs and maintain clear, seamless communication.

- Access to expert advice: We leverage our vast experience gained since 1906 to help you solve your production challenges. Our team is ready to work with your personnel to build a custom solution that meets your unique needs.

Ready to Elevate Your Production Processes?

Contact Our Team Today

Experience improved quality and productivity with Readco Kurimoto’s continuous process systems. Our equipment has maximized the competitive potential of many businesses over the years, demonstrating its ability to address processing gaps.

To get started, complete the contact form below, and we’ll get back to you shortly to discuss your needs.

Learn more about the products we’ve worked on by downloading our case studies.

Engineered and built in the United States of America

Engineered and built in the United States of America