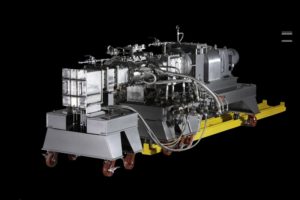

What Is a Continuous Hybrid Reactor, and How Does It Work?

Our Continuous Hybrid Reactor (CHR) is the newest member of our product lines. We have manufactured the CHR to facilitate safe, repeatable, and efficient chemical reactions in a variety of applications. The proprietary design utilizes deep vacuum, exceptional heat transfer, and agitation to perform a variety of complex reactions.

The CHR can process elastomers, adhesives, sealants, and other temperature- and/or oxygen-sensitive materials, and it allows for feeding of all primary liquids, slurries, or melted solid reactants, catalysts, and other reagents through injection ports in the barrel. This industrial mixing reactor can complete multiple tasks, including polymerization, slow and fast reactions, devolatilization, degassing, evaporation, solvent removal, and steam stripping.

The machine uses heat and vacuum (<10 Torr, 0.19 psi) combined with paddles that continuously agitate the material while exposing more of its surface area to assist with reactions, polymerization, and the removal of monomers, volatiles, moisture, or off-gasses from your product. If required, some of these by-products can be captured and recondensed for reuse or controlled disposal.

Learn More About Continuous Hybrid Reactors

Our continuous processing reactor can help your facility see streamlined production times and more consistent material reactions mixing. Get more information on how the Readco Kurimoto CHR can give you a competitive advantage by contacting us or exploring our resources below.

Downloads:

Downloads:

Continuous Hybrid Reactor Brochure (PDF)

Continuous Hybrid Reactor Handout (PDF)

Contact Our Team

If you are looking to gain a competitive advantage, Readco Kurimoto, LLC is a perfect choice for your most challenging processing needs. Fill out the form to contact our team and discuss your needs. We’ll be in touch shortly.

Engineered and built in the United States of America

Engineered and built in the United States of America